Categories

- "leverage ChatGPT (1)

- # vaccination (1)

- #🇺🇸 USA (2)

- #Addiction (1)

- #AI (2)

- #AI #Scope (1)

- #AI #Scope #Technology #Internet #computer (13)

- #AI #Scope #Technology #mobile (2)

- #AI Scope (1)

- #ancient #mythology (1)

- #ancient #mythology #history #Mexico (1)

- #apple #Scope #Technology #Internet #computer #iPhone (2)

- #artificial intelligence #future # memory #AI (3)

- #Asia (1)

- #bestchild (1)

- #bowler #international (1)

- #Brazil (1)

- #California (1)

- #Career (2)

- #cars (1)

- #childcare (1)

- #childhood #diwali #Gharonda #festival #hindusm #india (1)

- #china (1)

- #Communalism (1)

- #Connectevity (1)

- #corona (1)

- #Cricket (1)

- #Currency (1)

- #Death (1)

- #Delhi (1)

- #Donald Trump V/s Biden (1)

- #Duniyadari #ChatGPT #artificial #intelligence #machine #learning #mira #altman #ceo (1)

- #Duniyadari #ChatGPT #artificial #intelligence #machine #learning #money #altman #ceo (2)

- #Duniyadari #ChatGPT #artificial #intelligence #machine #learning #money #online (1)

- #Earthquake. #world news (1)

- #education (4)

- #Egypt (1)

- #Election 2020 (1)

- #Election in US (1)

- #englishmedium (1)

- #Euro 🇺🇸 USA (1)

- #Evergiven (1)

- #Evolution (1)

- #eye (1)

- #Facebook (1)

- #finance #usa (1)

- #first bionic eye #invention #world #science #health (1)

- #Football (1)

- #freedom (1)

- #g20 (1)

- #Gandhi (1)

- #girforest (1)

- #gods (1)

- #google (3)

- #gpt #Enterprise (1)

- #gpt #gpt4 (1)

- #Gujarat (2)

- #Happiness (1)

- #HappinessIndex #Global #World #GDP (1)

- #history #blogs (1)

- #Images #viral (1)

- #India (3)

- #India #Bharat # Old English (1)

- #international (1)

- #Internet (1)

- #Inventions (1)

- #japan #deities (1)

- #Job (1)

- #jobupdate (1)

- #Jyotirlinga (1)

- #life #motivation #habits #care #writing #blogs (1)

- #Lion (1)

- #local #guide #Google #map #help (1)

- #Mark Zuckeberg (1)

- #Mathematics #IMO #Olympiad #World #Talent #HOTS #Questions (1)

- #Mathematics #World #Talent #HOTS #Questions (1)

- #Meta (1)

- #misson (1)

- #Moderneducation (1)

- #modernschool (1)

- #money (1)

- #Moon (2)

- #Natural (2)

- #Natural #trending (1)

- #Naturalbeauty (2)

- #nature (3)

- #nature #cyclones #Biparjoy #news (1)

- #newschool (1)

- #Newyear (1)

- #Newyear #2022 #Newhope (1)

- #NTPC (1)

- #oldestschool (1)

- #Online #Free #Education #Technology #Best online #Courses (2)

- #OpenAI (1)

- #OpenAI #ChatGPT #News #USA #Artificial (1)

- #Over use (1)

- #Pandemic (1)

- #Passport #Singapore #Japan #Country (1)

- #prelearning (1)

- #preschool (1)

- #President #OxfordStudentUnion (1)

- #Racism (1)

- #RasmhiSamant (1)

- #Result (1)

- #Rio-de-Janerio (1)

- #robot (1)

- #RRB (1)

- #school (2)

- #Science (1)

- #Ship (1)

- #SirEdwinLutyen #Protest (1)

- #Somnath (1)

- #Space #Science #technology #education (2)

- #student (1)

- #SuezCanal (1)

- #technology #developed #learning #education (4)

- #US (1)

- #Varaval (1)

- #virtual (1)

- #vision (1)

- #World (2)

- #World #money #usa #news (1)

- #world news (3)

- #YouTube (1)

- 🇸🇾 Syria (1)

- 19October (1)

- 2023 (1)

- 2024 (2)

- 25 December (1)

- About Meta FACET Facebook (1)

- accurate answers (1)

- accurately diagnose illnesses (1)

- acess Chinese chatbot free (1)

- ActingSchool (1)

- Adidas (1)

- Admisson (1)

- Affordable AI model (1)

- AI (48)

- AI accessibility (1)

- AI and media partnerships (1)

- AI blog (1)

- AI blogs (3)

- AI Careers (1)

- AI chat solution (1)

- AI Christmas (1)

- AI creative task (1)

- AI Detection (1)

- AI Detection tools (1)

- AI future (2)

- AI Images (3)

- AI in 2024 (1)

- AI in e-commerce (1)

- AI in education (2)

- AI in recruitment (1)

- AI in technology (1)

- AI in Trading (1)

- AI laws (1)

- AI model pricing (1)

- AI models (1)

- AI news (5)

- AI pdf (1)

- AI performance benchmarks (1)

- aI prediction about Earthquake (1)

- AI research (1)

- AI safety measures (1)

- AI Scope (1)

- AI technology (2)

- AI Tourism (1)

- AI travelling (1)

- AI Wings image with chair (1)

- AI-driven recruitment ROI-positive AI (1)

- AI-powered news distribution (1)

- AICars (1)

- aidriven chat (1)

- AIScope (1)

- AIsearchengines (1)

- Alaska (1)

- algorithms (1)

- altman (3)

- altman sam (4)

- America 🇺🇸 opportunity (1)

- Ancient #USD (1)

- Android (2)

- Anger (1)

- Angkor wat (1)

- Angkor Wat history (1)

- Angkor Wat Photo (1)

- Animal (1)

- Animals (1)

- Apple (1)

- Apple Intelligence (1)

- Apple watch (1)

- apps (3)

- apps for mobile (1)

- architecture (1)

- Artificial (10)

- artificial #intelligence (1)

- artificial Intelligence (40)

- Artificial Intelligence Company (1)

- artificial intelligence future (2)

- Artificial Intelligence In Health (1)

- Artificial Plants (1)

- ascent (1)

- Ask questions (1)

- athlete (1)

- atom dot (1)

- attitudes (1)

- Aurangzeb (1)

- Automotive (1)

- avatar (1)

- Award (1)

- awareness (1)

- Bard (3)

- best (3)

- best AI (1)

- best AI avatars (1)

- best AI chat support (1)

- best AI tools (3)

- best apps android (1)

- best apps mobile (1)

- Best Awards (1)

- best blogs (2)

- best business ideas (1)

- Best Chatbot (2)

- best chatbots (2)

- Best chatbots 2023 (1)

- best Chess (1)

- Best Christmas wish (1)

- best earning ways (1)

- Best jobs (1)

- Best PM (1)

- best profitable startup (1)

- Best Prompts (1)

- Best Promts (1)

- Best School in India (1)

- Best Stocks (1)

- Best Teachers Award (1)

- Best Tools for AI Images Detection (1)

- best wall painting (1)

- best way to earn money online (1)

- Bharat (1)

- Bill Gates (2)

- Bing (1)

- bitcoin (1)

- blog (5)

- blog case studies (1)

- blog post (1)

- blog writing (1)

- Blogger (1)

- blogging (4)

- blogs (17)

- Board OpenAI (2)

- Brand (3)

- British 🇺🇸 (1)

- business (1)

- Cambodia Temple (1)

- Candidate matching (1)

- Cardiac Problems (1)

- care (1)

- Career (2)

- Careers (2)

- Careers turning point (1)

- Cars (1)

- CBSE (2)

- cctv (1)

- celebrate (1)

- celebration (1)

- CEO (7)

- CEO Rakuten (1)

- Chat GPT (6)

- chatbot (10)

- chatbot 2024 (1)

- chatbot for business (1)

- Chatbot Uses (1)

- chatbot2023 (1)

- Chatbots (11)

- chatbots for education (1)

- Chatbots in Future (1)

- Chatgpt (60)

- ChatGPT #google #technical (2)

- ChatGPT AI (1)

- ChatGPT alternatives (1)

- ChatGPT content integration (1)

- ChatGPT Illya (1)

- ChatGPT in Trading (1)

- ChatGPT jobs (1)

- Chatgpt news (1)

- ChatGPT Office (1)

- ChatGPT openai (1)

- chatgpt prompts (2)

- chatgpt prompts business (1)

- ChatGPT5 (1)

- Chess (1)

- Chess champion (1)

- chesscom (1)

- ChessGPT (1)

- china (3)

- China India (1)

- Chinese (1)

- Choice (1)

- Christmas (1)

- Christmas Quotes (1)

- Class-10 Science (1)

- clean city (1)

- Climate (1)

- Club (1)

- coding (1)

- coin launch cosmos (1)

- commonwealth chess (1)

- communication (1)

- computer (3)

- Condé Nast collaboration (1)

- Condé Nast publications (1)

- Consensus (1)

- contact testimonials team (1)

- conversational AI (1)

- copilot (1)

- Cost-efficient AI (1)

- countries (1)

- COVID-19 (1)

- COVID19 (1)

- create images (1)

- creativity (2)

- Cryptcurrency (1)

- Cryptography (1)

- CSS (1)

- Culture (2)

- custom AI (1)

- DALL-E (2)

- dalle (2)

- Dalle AI (4)

- dalleai (1)

- Dance (1)

- Data Analysis (1)

- data science (1)

- Day trading (1)

- Deal (1)

- Decoration (1)

- Deeplearning (1)

- desire (1)

- Desktop (1)

- Digital content licensing (1)

- Disaster (3)

- Dojo (1)

- Drawbacks Of Artificial Intelligence (1)

- Duniyadari (5)

- Duniyadari #ChatGPT (1)

- Duniyadari blog (1)

- Dwarka (1)

- earn (2)

- Earn Money (4)

- Earth (1)

- Earthday (1)

- Earthquake (2)

- ECG (1)

- economic (1)

- EdU (1)

- Education (13)

- education chatbon chatbot in education (1)

- Education Rural Development Better Future (1)

- Education sector (1)

- Educational (1)

- educational chatbot (1)

- Elon Musk (2)

- emotional AI (1)

- Emotions (1)

- ENGLISH (3)

- enhance legal aid with ChatGPT (1)

- Enhancedvisualsearch (1)

- Environment (1)

- Environmental Impact (1)

- Essentials Artificial Intelligence Laws (1)

- Ethical AI Development (1)

- face recognition (1)

- Facebook (3)

- FAQ (1)

- Fashion (1)

- featuring (1)

- festival (1)

- Financial Technology (1)

- Fire (1)

- Fire In Forest (1)

- first ai (1)

- First AI in Iraq (1)

- First Artificial Intelligence I AI (1)

- First case of Corona (1)

- Folk (1)

- Food (1)

- Football (1)

- for nonprofits (1)

- forfuture growth engineopenai (1)

- Foundation (1)

- Free AI courses (1)

- Free chatbots for users (1)

- free earning tips (1)

- Free Prompts (1)

- freelance marketplace (1)

- freelancer experience (1)

- Frustration (1)

- Function (1)

- future (3)

- future AI (1)

- future chatbots (1)

- Future Search engine (1)

- game (1)

- Games (1)

- Garry Kasparov (1)

- Gemini (1)

- generative AI (4)

- Global (1)

- global warming (1)

- Goal (1)

- goodness (1)

- Google (9)

- Google Adsense (1)

- Google Bard (4)

- Google certificate (1)

- Google course free with certificate (1)

- Google Gemini (1)

- Google lense (1)

- Government (2)

- Government College for acting (1)

- gpt (4)

- GPT models (1)

- gpt prompts (1)

- GPT Store (1)

- GPT-3 (1)

- GPT-4o (1)

- GPT-4o Mini (1)

- GPT4 (1)

- Grammar (1)

- Greatest Awards (1)

- Greatest Player (1)

- Grimoire (1)

- Grocery (1)

- Grok (1)

- Grokai (1)

- growth engineopenai potential (1)

- guard (1)

- Gujarat (1)

- habits (1)

- happiness (2)

- happy birthday (1)

- Happy new Year (1)

- Hawai (1)

- Health (1)

- health and wellness (1)

- healthcare (3)

- Heartbeat (2)

- help students homework (1)

- Heritage (1)

- highly risky regulatory (1)

- History (2)

- how does OpenAI Make money (1)

- hugging face (1)

- Huggingface (1)

- Humen actvities (1)

- Ideas (1)

- Illya Sutskever (1)

- Image (2)

- images (1)

- images Editing (1)

- Immersity AI (1)

- Impact (1)

- inaugural (1)

- Indeed Invite to Apply feature (1)

- Indeed and AI integration (1)

- India (5)

- Indicator (1)

- industry leader (1)

- infant (1)

- information (1)

- instagram (2)

- intelligence (4)

- Intercom (1)

- international gaming company (1)

- Internationalexam (1)

- Internet (4)

- Internet computer (1)

- interview (1)

- Intraday Tips (1)

- Intrest (1)

- Investment (1)

- Investment Algorithmic Trading (1)

- Investors (1)

- iOS (1)

- Iphone (1)

- isro (1)

- It's Effect . (1)

- Japan (2)

- Job (3)

- Job In California (1)

- Job market trends (1)

- Job seeker experience (1)

- job updates (1)

- Jobs (3)

- journalism (1)

- Jr.NTR (1)

- Junagadh| Gujarat| India (1)

- keyword (1)

- kickstart (1)

- Kiribati 🇰🇮 (1)

- Kraftful Products Coach (1)

- kyutai (1)

- language (1)

- language model (2)

- Largest Temple in the world (1)

- learn prompts (1)

- Learn stock market (1)

- learn with AI (1)

- learning (1)

- learning precision medicine (1)

- life (3)

- Lightning AI (1)

- LitGPT (1)

- live images monolisa (1)

- LlaMa (1)

- LLM (9)

- LLMs (1)

- London (1)

- loopt y combinator openai (6)

- Low-cost AI applications (1)

- Luxury (1)

- machine (1)

- machine learning (6)

- Mails (1)

- make life easier (1)

- Malaysia (1)

- Man. (1)

- Maradona (1)

- market (1)

- Market Prediction (1)

- Marking Scheme (1)

- Mathematics (1)

- maths question (1)

- maximize benefits of AI technology (1)

- Medical (1)

- Medical Exam (1)

- Melaka Chess. (1)

- Memory (3)

- Merry Christmas (1)

- Meta (1)

- Meta AI WhatsApp (1)

- Meta chatbot (1)

- MetaAI (1)

- metaoneverse (1)

- Microsoft (10)

- Midjourney (1)

- minds (1)

- Mira (1)

- Mira Murati (1)

- Mobile (1)

- monalisa (1)

- money (5)

- money profit (1)

- Moshi AI (1)

- motivation (1)

- moves (1)

- Movie (1)

- Multimodal reasoning (1)

- Murati (1)

- Naatu-Naatu Song (1)

- Nacho-Nacho (1)

- nasal (1)

- National Research (1)

- National Youth Day (1)

- Nattu-Nattu (1)

- Natural Disaster (2)

- Natural disasters (1)

- natural language processing (2)

- Natural Language Processing (NLP) (1)

- Nature (2)

- NCERT (1)

- NEET (1)

- nevergiveup (1)

- New ads policy (1)

- new AI code (1)

- New model (1)

- News (17)

- NextGen (1)

- nlp (1)

- NSD (1)

- NTA (1)

- Occupied kasmir by India (1)

- Ocean (2)

- OECD (1)

- Office (1)

- online (1)

- Online Course (1)

- online education (1)

- online money using ChatGPT (1)

- OpenAI (64)

- OpenAI ChatGPT News USA Artificial (1)

- Openai Career (1)

- OpenAI fine-tuning (1)

- OpenAI partnership (1)

- openai sam altman (7)

- Openlayer (1)

- opinion words data-driven (1)

- Opportunity (1)

- Oscar Awards (1)

- Pakistan (1)

- Pakistan and China (1)

- Parajumble Questions (1)

- Personalized searchresults (1)

- phile (1)

- Photo (1)

- photo Editing (1)

- PM Modi (1)

- PM of India (1)

- Podcast (1)

- pollution (1)

- Popular Question USA (1)

- Positional Trading (1)

- positions (1)

- positive (1)

- post (1)

- Prince Action Trading (1)

- Prize (1)

- product development (1)

- product nfts (1)

- productivity (1)

- programming (2)

- prompt (1)

- prompt engineering (1)

- Prompt writing Tips (1)

- Prompts (4)

- Prompts engineering course (1)

- Promt writing Tips (1)

- Protection (1)

- PyTorch Lightning (1)

- Question Paper (1)

- quotes (1)

- Rajouri (1)

- Rakuten (1)

- Rakuten deal openai (1)

- Ramcharan (1)

- Real-timedataanalysis (1)

- receives equity stake (1)

- recent monetization openai (1)

- recognize patterns medical (1)

- Redcliff (1)

- reduce burden hr (1)

- research (2)

- Resignations (1)

- responsible gaming (1)

- richest (1)

- rocket (1)

- Rockset (1)

- RRR (1)

- safety (1)

- sam (4)

- sam altman (9)

- sam altman ai (6)

- sam altman ceo (1)

- sam altman investments (2)

- sam altman linkedin (6)

- sam altman open ai (6)

- sam altman openai (6)

- sam altman y combinator (6)

- Sam Fired (1)

- sapcex (2)

- Scalping (1)

- Scholarship (1)

- Schools (1)

- Science (1)

- Scope (3)

- ScopeofMaths #Mathematicalproblemsolving #Skills #process (2)

- search engine (3)

- search engine market (1)

- searchgpt (1)

- SearchGPT prototype (1)

- Season (1)

- Secured Jobs (1)

- Sengol Narendra Modi (1)

- SenseNova (1)

- SenseTime (1)

- seo (1)

- Series 5 (1)

- services (1)

- share market (1)

- shares price initially (1)

- Siri (1)

- snakes (1)

- Soccer (1)

- software (1)

- sorrow (1)

- space (1)

- Spoken practice (1)

- Sports (2)

- St. George (1)

- Stability AI (1)

- Stable Diffusion3 (1)

- startup (2)

- startups (1)

- Stethoscope (1)

- Stock Analysis (1)

- Stock Market (1)

- Stocks in English (1)

- Strawberry project (1)

- Sudarshan Setu (1)

- suffix (1)

- Superhit (1)

- Swing Trading (1)

- Synthesia AI (1)

- system Cards (1)

- Teacher (1)

- Teaching (2)

- tech (1)

- tech blogs (1)

- technological (1)

- Technology (38)

- Technology #Internet #computer (1)

- technology curve (1)

- Technology in 2024 (1)

- Technology mobile (1)

- Telugu (1)

- Tesla (2)

- Text and vision support (1)

- think big (1)

- Thom Browne (1)

- Tim cook (1)

- time (1)

- Titan Submarine (1)

- Titanic (1)

- top (1)

- top talent (1)

- Top University (1)

- Topper (1)

- toung twister (1)

- tourism (1)

- trading (2)

- Trading Strategies (1)

- Trails (3)

- travelling (2)

- travelling for all (1)

- trend opinion world (1)

- Trending (1)

- Trends (1)

- Turkey 🇹🇷 😢 (1)

- tutoring course creation (1)

- TwitterX (1)

- UAE (1)

- UNESCO (2)

- United State (1)

- Upwork (2)

- US (3)

- USA (7)

- USA Artificial (1)

- use ChatGPT (1)

- users (2)

- Vaccination (1)

- Valentine (1)

- variety (1)

- Varkey (1)

- venomous (1)

- Veteran (1)

- Vignette Ads (1)

- virtual assistant (1)

- virtual chat agent (1)

- Voicesearchoptimization (1)

- wall painting (1)

- wealth (3)

- wealth creation (1)

- weight loss (1)

- Whatsapp (1)

- WhatsApp telegram community (1)

- when (1)

- where why (1)

- which is better chatbots (1)

- wild (1)

- Wishes (1)

- Women in AI (1)

- work (1)

- Worlclassbrand (1)

- world (7)

- World artificial intelligence (1)

- World best Apps (1)

- World news (1)

- world predator (1)

- world's first (1)

- writing (2)

- Wuhan (1)

- X (1)

- Xtuner (1)

- Y (1)

- y combinator sam altman (6)

- Youth (1)

- Zico Kolter (1)

- माँ पिता परमेश्वर (1)

- शातिर अपराधी विकास दुबे (1)

https://www.facebook.com/profile.php?id=100080054237461

Recent Posts

Blog Archive

-

▼

2023

(119)

-

▼

November

(21)

- OpenAI's Confusion not good for AI Safety: Micros...

- Jobs At OpeAI:World's Largest Artificial Intellige...

- You have Never Seen Such beautiful Images of 8th W...

- Create Your Own ChatGPT and Make Money From It Wit...

- Getting Sam Altman back as CEO of OpenAI was not p...

- Finally Sam Altman's OpenAI 5 Days Drama In OpenAI

- Sam Altman's Lecture On Stanford University about ...

- OpenAI board in discussions with Sam Altman to ret...

- Who is Ilya Sutskever, the man at the center of Op...

- ChatGPT Loses It's Best Fundraiser

- Everything About OpenAI Company Board of Members a...

- OpenAI Unveils Changes in Leadership

- Who is Mira Murati Interim CEO Of OpenAI

- Sam and I are shocked and saddened by what the boa...

- ChatGPT Creator Sam Altman Fired From OpenAI

- 7 Best Way To Make Money With AI in 2023

- World's First: 3D Printed Robotic Hand with Functi...

- "Empowering Users: OpenAI Unveils a 'No Coding Req...

- ChatGPT+ Will Be Able To Speak,Hear And See

- OpenAI's GPT-4 Turbo in Preview: Sam Altman

- Error Rate Has Decreases ChatGPT: OpenAI

-

▼

November

(21)

Search This Blog

Search This Blog by Duniyadari AI blogs

AI Blog

Ad Home

Recent Posts

Duniyadari MishraUmesh07 Blog was Founded by Umesh Mishra more than 300 AI blogs you can read!

Variables / Comments

Get Gifts

Contact Form

Translate

Follow Us

https://instagram.com/insurancepostindia?igshid=ZGUzMzM3NWJiOQ==

About

Beyond the Technology We are writing about world ,India Heritage, nature and latest news

Duniyadari MishraUmesh07 Blog was Founded by Umesh Mishra more than 300 AI blogs you can read!

Blogroll

Comments

Most Recent

Future of Artificial Intelligence

August 28, 2024

How OpenAI Works

August 17, 2024

OpenAI’s acquisition of Rockset

August 05, 2024

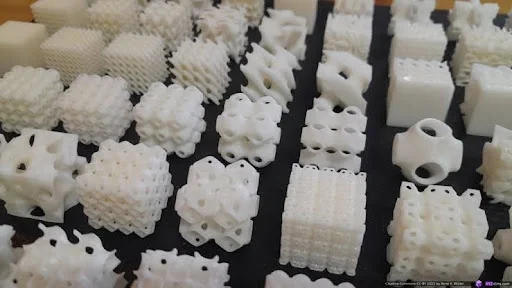

World's First: 3D Printed Robotic Hand with Functioning Bones, Ligaments, and Tendons

Mishraumesh07

November 16, 2023

The novel approach employed by the researchers signifies a departure from conventional 3D printing methodologies, incorporating a laser scanner and a feedback mechanism to achieve unparalleled precision in the construction process. Unlike previous attempts limited by the constraints of fast-curing polyacrylates, this advanced technique has enabled the realization of a robotic hand with a level of complexity and durability previously deemed unattainable.

Robert Katzschmann, a distinguished professor of robotics at ETH Zurich and the driving force behind this next-generation robotic hand, emphasized the pivotal role played by this groundbreaking technology. He stated, "We wouldn't have been able to fashion this hand using the fast-curing polyacrylates we've relied on in 3D printing thus far." The successful integration of cutting-edge components not only propels the field of robotics forward but also promises a future where robots can be designed with unprecedented intricacy and resilience.

The implications of this achievement extend beyond the creation of a robotic hand; they signal a paradigm shift in the possibilities of constructing sophisticated and robust robotic systems. As researchers continue to push the boundaries of innovation, the trajectory of robotics appears poised for remarkable advancements, with implications ranging from healthcare to industry and beyond. This groundbreaking endeavor not only exemplifies the prowess of the scientific community at ETH Zurich but also beckons a future where the boundaries of what can be achieved in robotics are continually redefined.

In the realm of robotics, Professor Katzschmann, the mastermind behind our innovative soft-material hand, sheds light on the distinctive advantages that these pliable creations offer over their metal counterparts. According to him, the inherent softness of such robots not only minimizes the risk of injury when collaborating with humans but also enhances their capability to delicately handle fragile items.

In contrast to the strides made in industrial robotics, which have undeniably progressed in recent years, there remains a substantial concern regarding the potential hazards they pose to human counterparts sharing their workspace. A poignant incident from just this month serves as a stark reminder: a South Korean man tragically lost his life when a machine, misconstruing him for a mere box of vegetables, exerted fatal force.

The groundbreaking soft robotic hand, chronicled in a recently published paper titled 'Vision-controlled jetting for composite systems and robots' in the esteemed scientific journal Nature, not only represents a technological marvel but also hints at a transformative shift in the landscape of robotics. This subtle evolution, propelled by the intrinsic qualities of soft materials, not only prioritizes safety in human-robot interactions but also revolutionizes the handling of delicate and breakable objects. As we delve into the future of robotics, the pliability of these creations stands as a testament to the potential for safer and more refined collaboration between man and machine.

The Marvels of 3D Printers

In the realm of technological wizardry, where innovation converges with imagination, 3D printers stand as the architects of a renaissance in creation. These extraordinary machines are not just tools; they are portals to a world where the digital realm materializes into tangible, three-dimensional wonders. Let's embark on a journey through the captivating landscape of 3D printing, exploring its profound impact on industries, creativity, and the very fabric of our future.

The Symphony of Layers: How 3D Printing Works

At its core, 3D printing is a symphony of layers, a ballet of precision that transforms digital blueprints into physical reality. The process, also known as additive manufacturing, involves layering material—typically plastic, metal, or resin—one thin slice at a time, gradually building up the final object. It's akin to watching a sculpture come to life, layer by intricate layer, under the meticulous guidance of technology.

Beyond Prototypes: Reshaping Industries

While 3D printing started as a prototyping marvel, it has now evolved into a transformative force across diverse industries. From aerospace to healthcare, automotive to fashion, 3D printing has woven its way into the fabric of innovation. In aerospace, intricate components are crafted with unparalleled precision, reducing weight and improving fuel efficiency. In healthcare, the technology breathes life into the concept of personalized medicine, with 3D-printed organs and prosthetics changing the landscape of patient care. The adaptability of 3D printing has even permeated the culinary world, where chefs explore the boundaries of gastronomic artistry layer by delectable layer.

Empowering Creativity: From Hobbyist to Artisan

The democratization of creativity is arguably one of the most enchanting aspects of 3D printing. What was once the exclusive realm of industrial giants has now found its way into the hands of enthusiasts and artisans alike. Home 3D printers empower individuals to turn visions into reality, fostering a maker culture that thrives on innovation and personal expression. Whether it's crafting intricate jewelry, architectural models, or bespoke home decor, 3D printing transforms every space into a haven for boundless creativity.

A Sustainable Symphony: Reducing Waste and Carbon Footprints

In an era where sustainability is non-negotiable, 3D printing emerges as a champion in the fight against waste. Traditional manufacturing processes often result in substantial material wastage, but 3D printing mitigates this by constructing objects layer by layer, with minimal surplus. Additionally, the ability to recycle materials in certain 3D printing processes contributes to a more sustainable and eco-friendly production cycle. As industries and consumers alike strive for greener practices, 3D printing stands as a beacon of innovation in harmony with the planet.

Challenges and Future Horizons: Navigating the Uncharted

However, the symphony of 3D printing is not without its challenges. Quality control, material limitations, and the need for standardization are hurdles that the industry continues to address. As we navigate the uncharted territories of this revolutionary technology, the horizon is rife with possibilities. From the prospect of 3D-printed homes to advancements in bioprinting, where living tissues are constructed layer by layer, the future promises a crescendo of breakthroughs that will reshape the very fabric of our existence.

In the grand tapestry of technological wonders, 3D printers stand as both artisans and architects, sculpting a future where the boundaries of creation are bound only by imagination. As this symphony of layers continues to unfold, it invites us to marvel at the extraordinary potential nestled within each meticulously crafted stratum, beckoning us to dream, design, and redefine what's possible.

Popular Posts

AI in Travelling

June 14, 2024

Error Rate Has Decreases ChatGPT: OpenAI

November 02, 2023

Future AI Cars Artificial Intelligence in Automotive Industry

October 19, 2023